DE850A2-Laser500 Edge Banders

Automatic Flexible Edge Banding Machine

DE850A2-Laser500 Automatic Flexible Edge Banding Machine

The appearance may be updated at any time. There may be a delay in website updates. The latest design is the final version.

UNISUNX You Can Rely on

Our products include: Panel saw (including Z and Y series), edge banding machine, reciprocating saw series, over-edging machine, CNC processing center, carving machine series and so forth, which are exported to more than 50 countries and regions, such as Europe, Russia, Southeast Asia, Middle East, North America, Australia. It has established complete sales system (more than 120 dealers). Over yeas of experience in competitions in domestic and overseas markets, our brand has become one of global well-know brand, which offers trustworthy machinery for global customers.

Details That Make the Difference

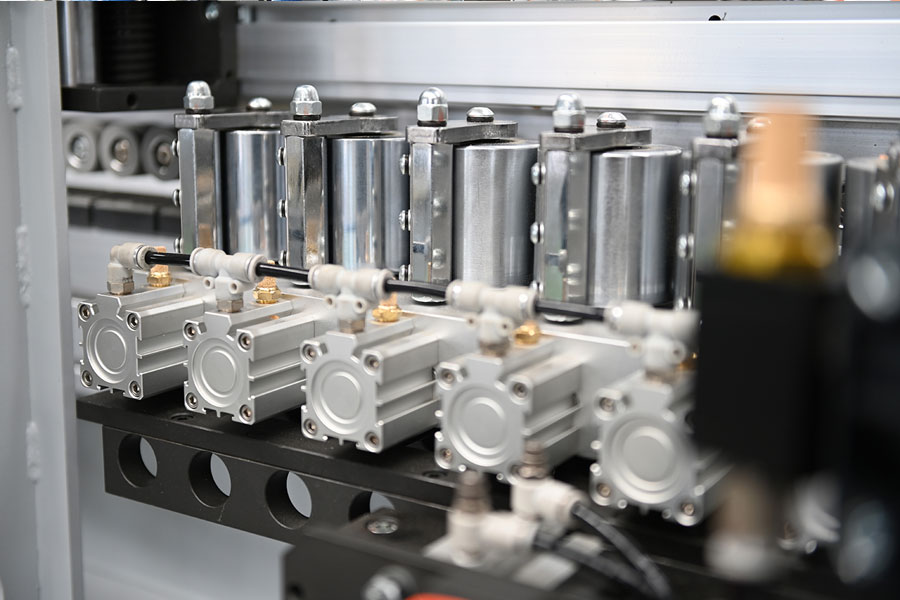

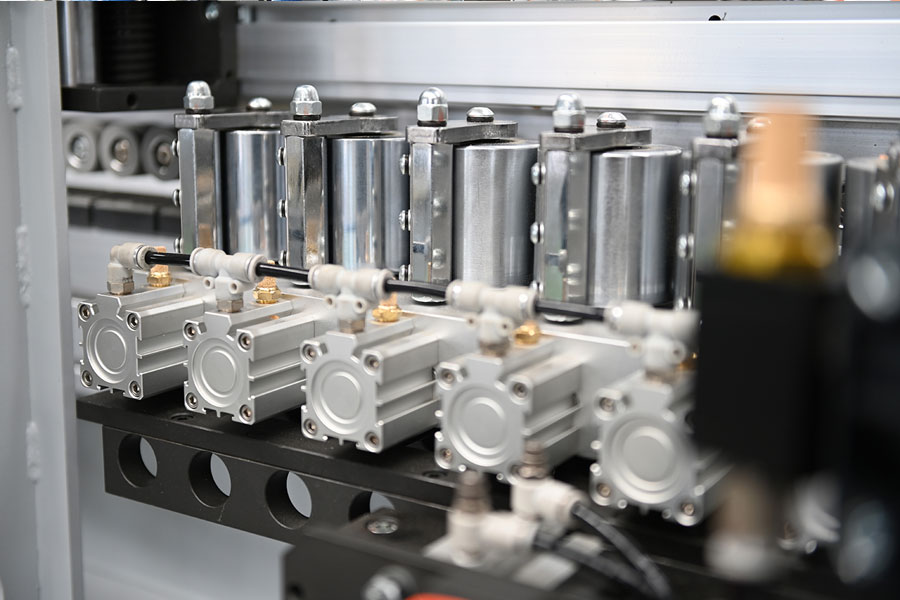

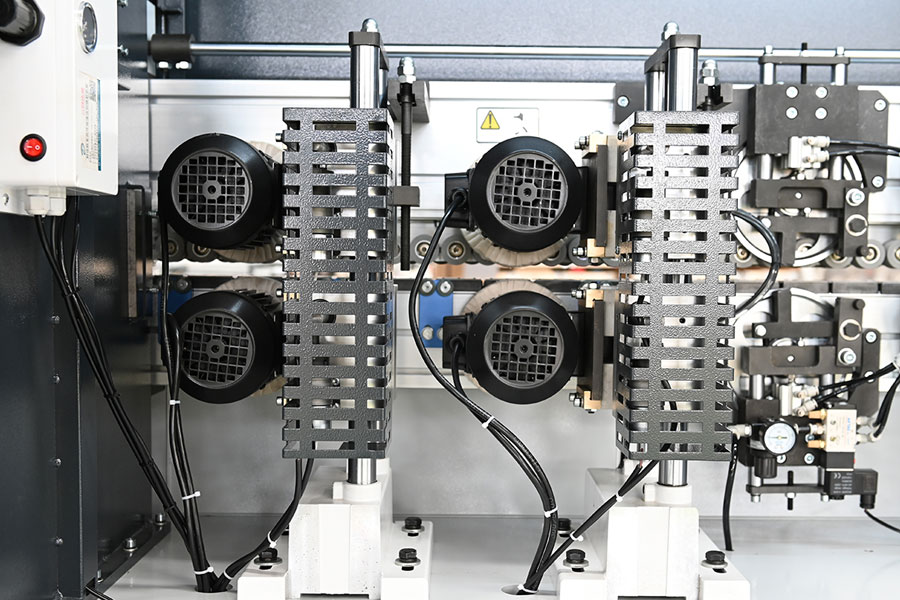

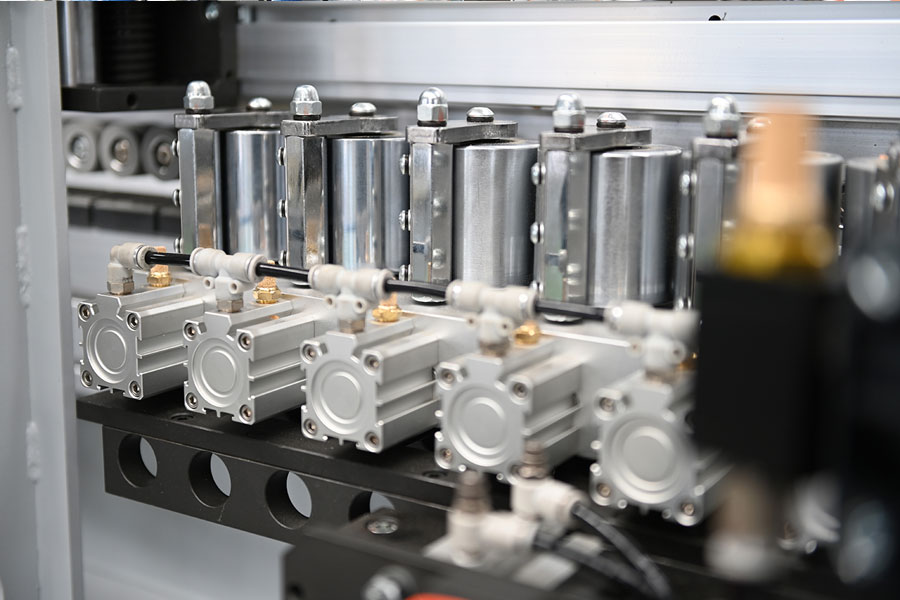

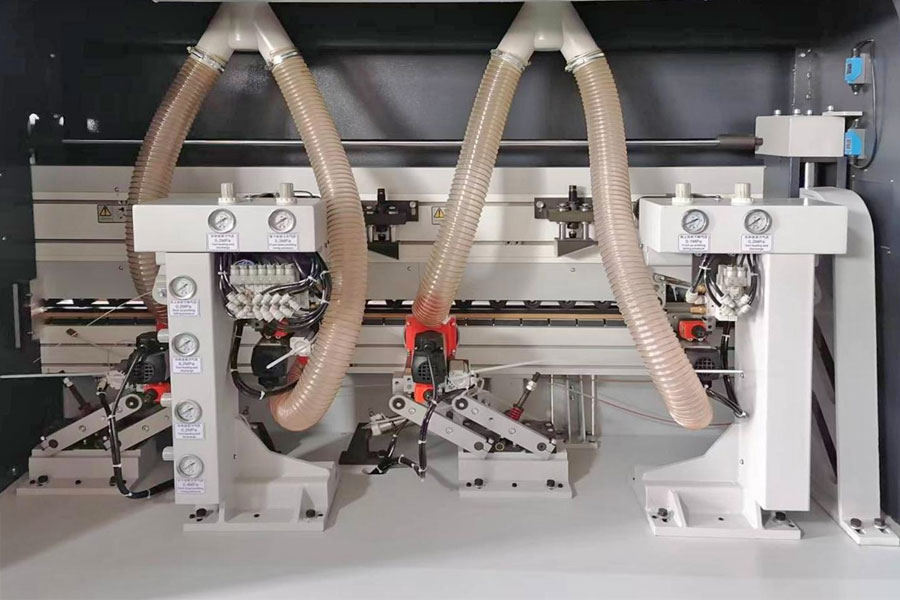

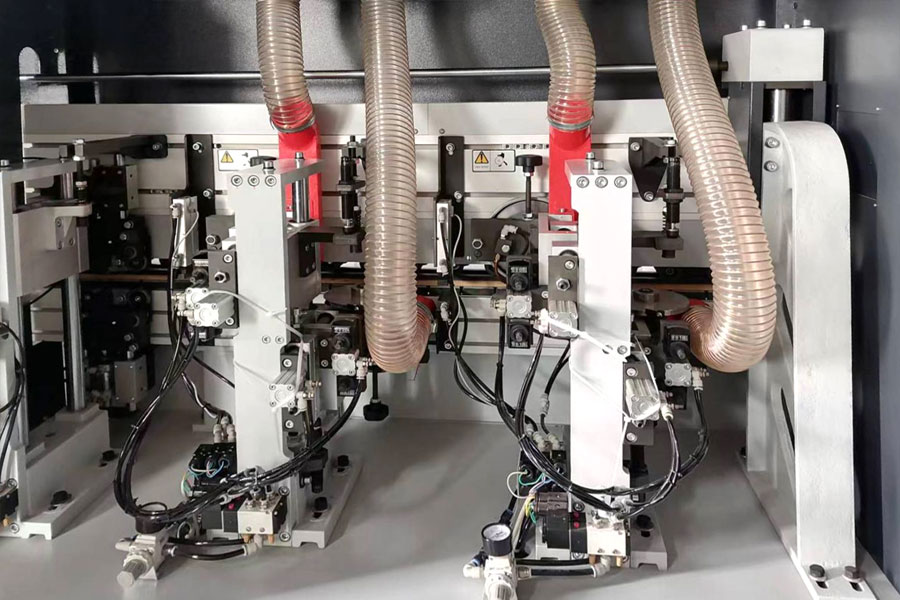

Fast glue pressing system

Fast glue pressing system

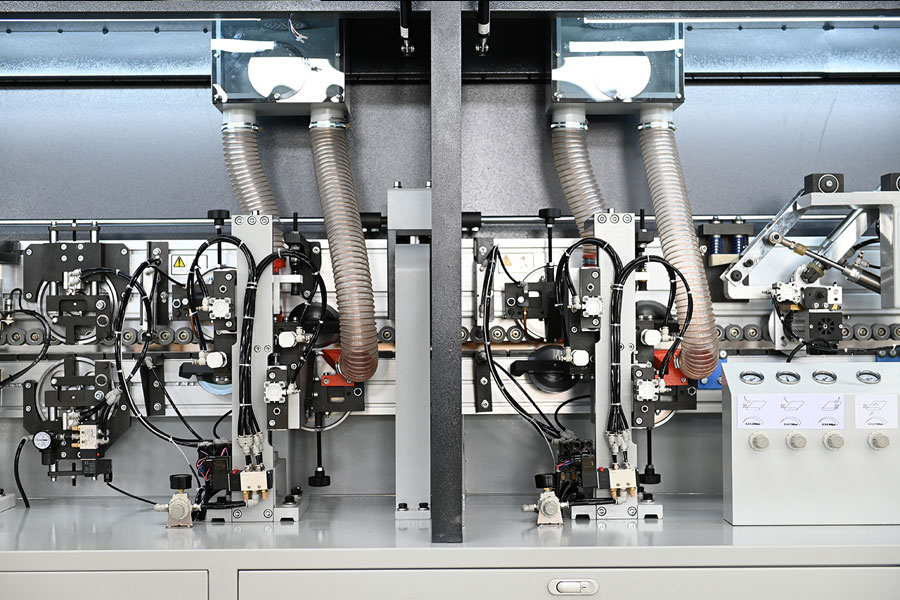

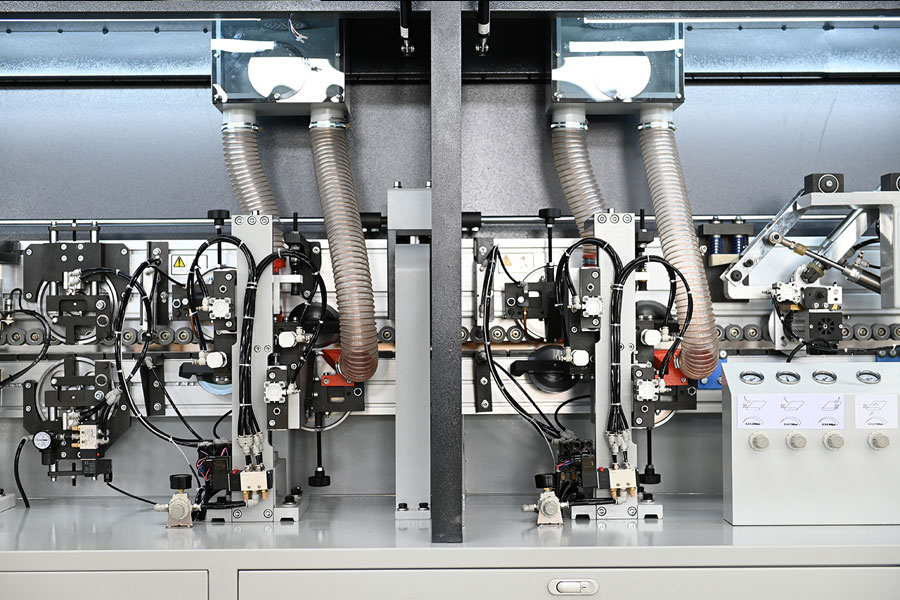

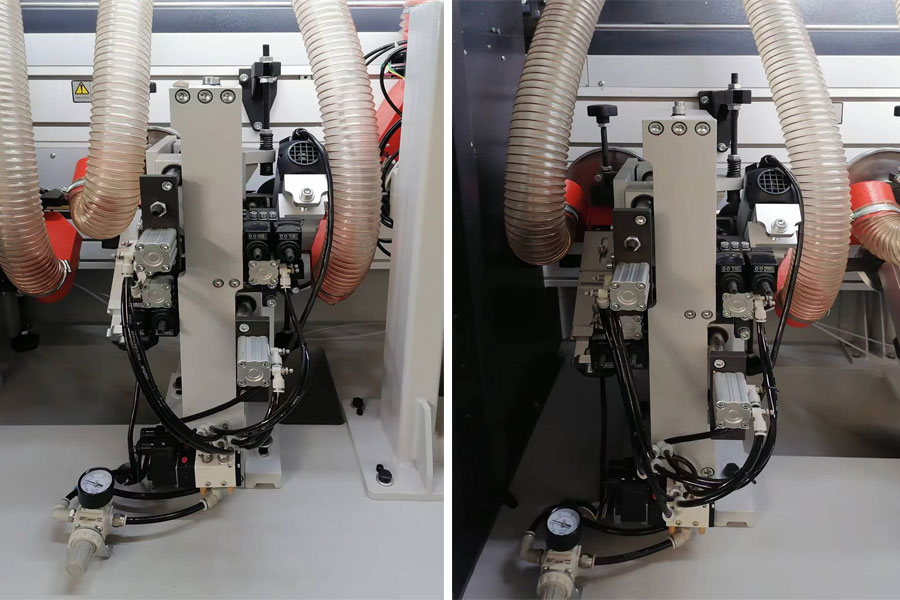

Double pneumatic edge scraping device

Double pneumatic edge scraping device

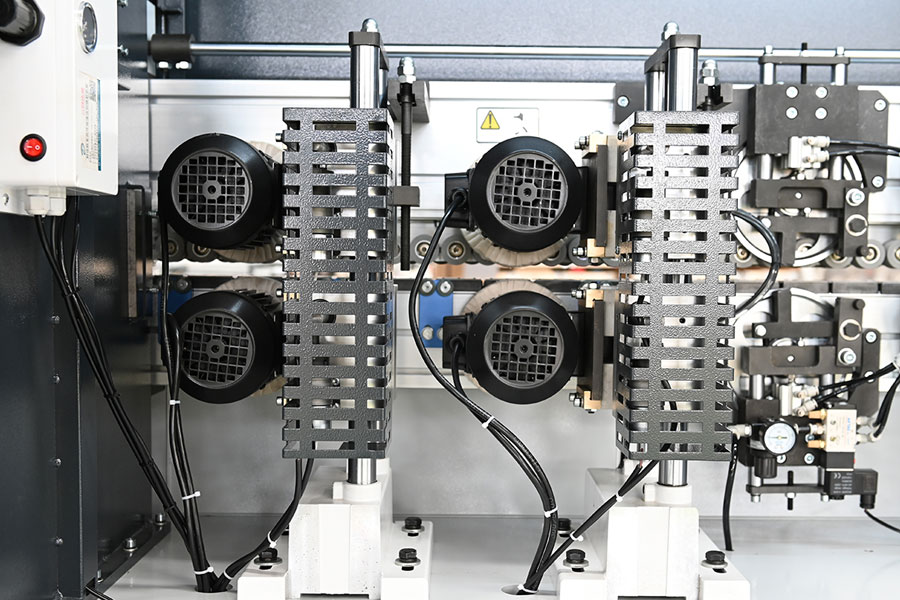

Double motorizing polishing

Double motorizing polishing

DE850A2-Laser500 Automatic Flexible Edge Banding Machine

- Laser seamless edge banding, rectangular uniform spot. computer control

- Track pressure canal

- Two-color PUR glue pot switching+Two sets of Lasar edge banding unit, Double guide rail end trimming, Four knives proflling unit

Details

Two glue pots using five rounds of pressing, standard with scraping film.

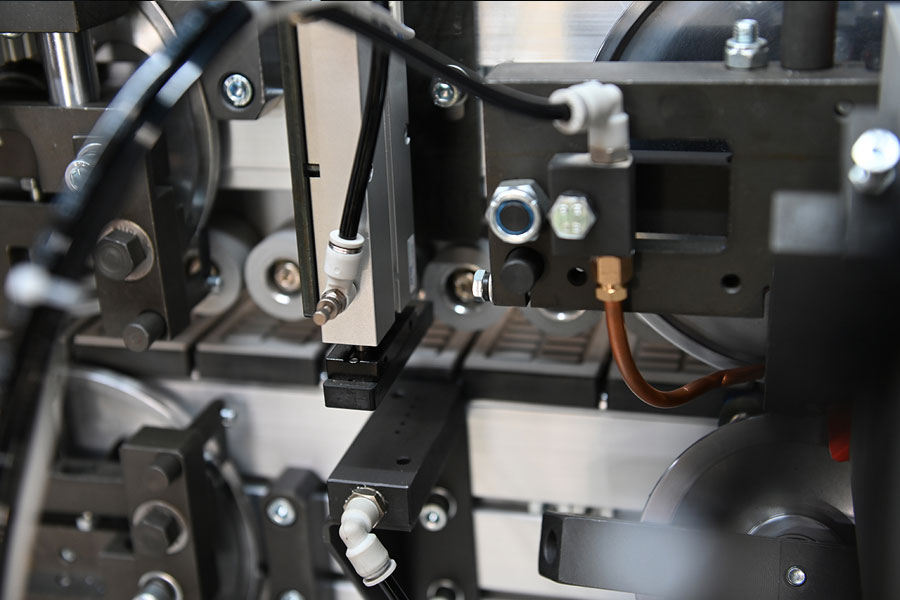

According to the thickness of the edge tape automatic switch, used to repair processing plate edge sealing strip up and down the excess part of the edge sealing material, to ensure that the upper and lower parts of the trimming plate smooth.

UNISUNX patented technology, high precision copying to ensure the finished product effect; Can repair both sides of the fillet, double motors to repair the Angle copying, each motor power 0.3kw, frequency 200hz, speed 12000rpm; Planar connecting rod mechanism, two copy milling cutter, make the end face of the plate more smooth and beautiful; Can also track the repair edge, according to the needs of the repair of different shapes of the edge.

Technology Data

| Total power | Standard:34.45kw Laser:3kw |

| Overall dimensions | 12310 x 2185 x 2020mm |

| Feed speed | Standard:8-33m/min Laser:15-20m/min |

| The thickness of the sheet metal | Standard:10-60mm Laser:10-50mm |

| Sealing tape thickness | Standard:0.4-3mm Laser:0.8-3mm |

| Sheet metal width | ≥80mm |

| Work pressure | 6MPa |

| Weight | 5660kg |